Gas Detector

Fall 2022

7 weeks

Hand prototyping

Branding

Solidworks

Keyshot

An iconic gas safety device, reimagined.

Before attaching the pump, the clip and battery cover must be removed from the Ventis Pro5 with a screwdriver. The latter is because the pump needs to be installed onto and share the monitor’s battery. This process is laborious for a user who is switching between modes multiple times a day.

Wearable mode

Pain point: conversion process

Sampler mode

I felt that the most important thing to keep in mind was flexibility and frictionless interaction. Gas monitors already pose a slight inconvenience for those who have to wear them for hours at a time in the field. At the very least, the operation of the device and conversion process should be absolutely seamless.

In addition, I wanted to infuse a little more “whimsy” into the form, using a combination of playful curves and geometric details to give the object a delightful presence.

The screen and buttons of the Ventis are now at the top, allowing for better visibility and more comfortable interaction. The panic button has also been relocated to the side to give it its own space.

The pump attachment has been redesigned to contain its own battery, meaning it can attach to the Ventis without the need for removal of battery pack with a screwdriver. Additionally, the new design and placement of the pump allows the clip to remain attached as well.

The new conversion process can be completed in seconds.

In this sponsored project we worked with Industrial Scientific, a Pittsburgh-based safety technology company, to propose redesigns for some of their most successful products. The company, while large, doesn’t have in-house designers, instead outsourcing this work to other companies. We wanted to give their product line the treatment of an in-house design team, complete with visual branding.

Ventis Pro5: Overview

Each of us worked individually on a different Industrial Scientific product. I was working with the Ventis Pro5, a wearable device that, with the use of an attachment, can also be used as a remote sampling device.

Most products offered by the company are either a wearable or a sampler, so the flexibility offered by the Ventis Pro5 is unique.

The Ventis Pro5 has five gas sensors at the top of the device face. When used as a wearable, these sensors work passively, monitoring their immediate area. When used as a sampler, the pump attaches to these sensors and samples air from a distance.

The panic button, located between the sensors, can be pressed to immediately alert other devices to an issue.

There are two buttons on the Ventis Pro5. Gas readings, battery level, and other information can be read on the screen.

Pain point: interface placement

The screen and buttons of the Ventis Pro5 are at the bottom of the device. This makes the buttons hard to access when the device is used one-handed, especially when the user’s thumb flexibility is inhibited by work gloves.

Additionally, the direction from which the thumb travels to the buttons means that the screen is obscured when the buttons are being used.

Finally, because the panic button is placed between sensors, the pump cover has a pseudo-button that transfers a press to the panic button below.

My design

My design incorporates interface changes and a playful form factor into a possible Ventis Pro5.

Panic lights flash to alert the user to danger or man down.

Process

I wanted to focus on the Ventis Pro5’s strong points and make them stronger. The flexibility of the Ventis Pro5 to function as both a wearable and sampler is unique in Industrial Scientific’s product line, so I wanted to focus on that conversion process.

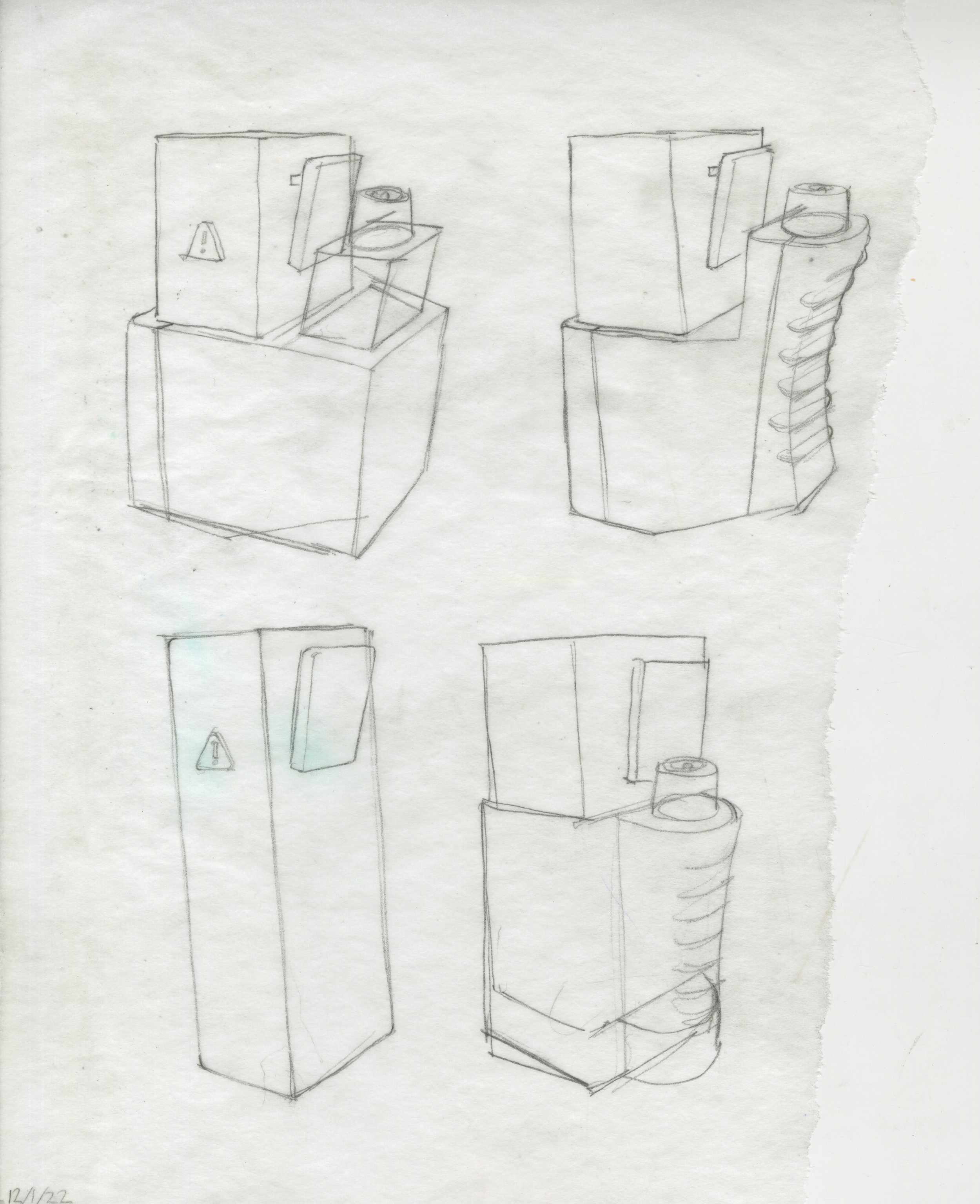

I began by exploring novel ways of connecting the pump to the Ventis. My first ideas were very speculative and were focused on delightful and playful interactions.

As I move forward in modeling, I began to pay more attention to the dimensions of the battery and sensors that would need to fit into the design. I tried to keep these in mind but not let them hold me back.

At this point I began developing the bottom-mounted pump. This concept emerged to accommodate the interface rearrangement. The shape of the pump was designed around the wearable clip, so it wouldn’t need to be removed during the conversion process. The pump was also designed to accommodate its own battery.

The final form giving was done in Solidworks.